When it comes to the world of ropes, strength, durability, and versatility are the name of the game. Whether for outdoor activities, industrial use, or simple household chores, the type of rope you choose can make a world of difference. Among natural fibers, two stand out as popular choices: hemp and cotton.

Is hemp rope stronger than cotton rope? This query leads us down an intriguing path, exploring not only the innate characteristics of these fibers but also the scientific evidence that supports their respective strengths and weaknesses. In this beginner-friendly guide, we’ll delve into the comparative analysis of hemp and cotton ropes, answering essential questions, and providing expert insights to enable you to make informed decisions.

- The Origin of Hemp and Cotton Ropes

- Hemp Ropes: A Rich History and Strong Composition

- Cotton Ropes: Soft, Flexible, and Widely Used

- Comparative Strength: Is Hemp Rope Really Stronger than Cotton?

- Economic Considerations: What Are the Costs Involved?

- Health and Safety: Are There Any Health Risks or Benefits?

- Conclusion

- FAQs

The Origin of Hemp and Cotton Ropes

Understanding the source and manufacturing process of hemp and cotton ropes helps demystify their distinct properties. Here, we’ll explore the composition, historical usage, and essential characteristics that define these two types of ropes.

Hemp Ropes: A Rich History and Strong Composition

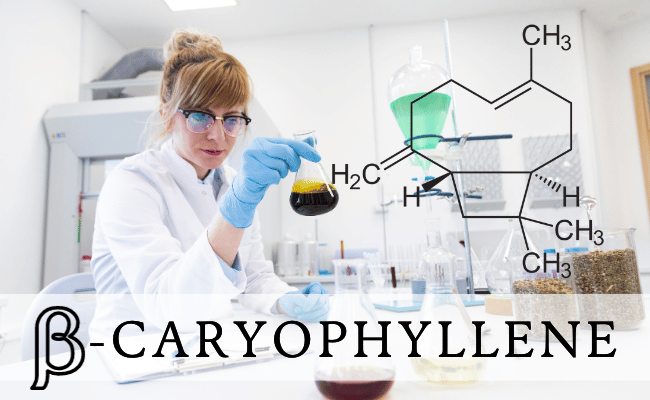

Hemp ropes are made from the fibers of the hemp plant, scientifically known as Cannabis sativa. This plant has been cultivated for various uses, including textiles and ropes, for more than 10,000 years. A study conducted by archaeologists in ancient Mesopotamia revealed the presence of hemp fibers, which highlights the historical significance of hemp ropes.

The strength of hemp ropes lies in their robust fiber structure. According to research published in the “Journal of Materials Science and Engineering,” hemp fibers possess high tensile strength, elasticity, and resistance to microbial activity. These properties make hemp ropes highly desirable for applications requiring durability and resilience.

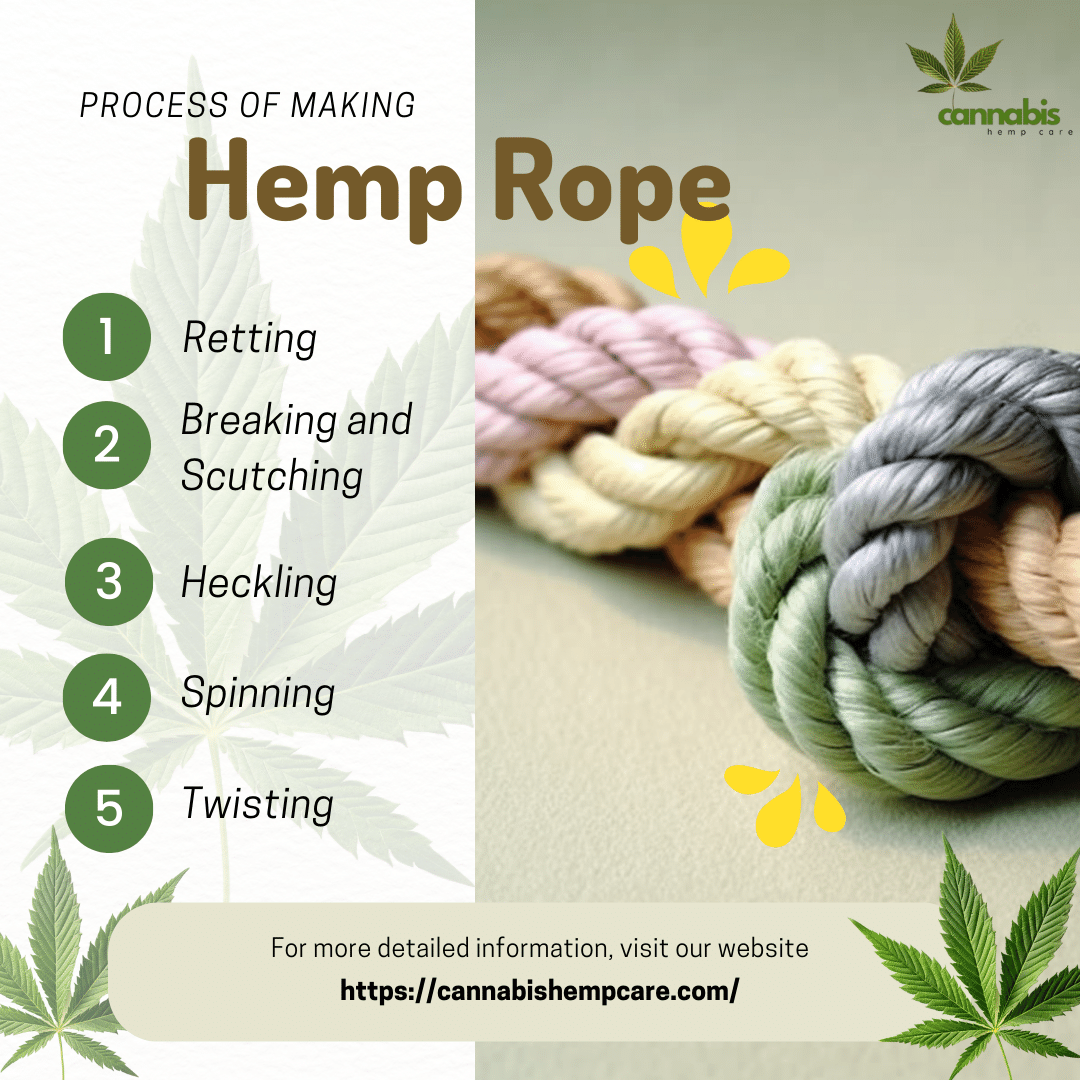

The process of making hemp ropes involves the following steps:

- Retting: Hemp stalks are soaked in water to loosen the fibers.

- Breaking and Scutching: The fibers are separated from the woody parts of the stalk.

- Heckling: Fibers are combed to align them.

- Spinning: The aligned fibers are spun into yarn.

- Twisting: Yarns are twisted together to form the final rope.

Cotton Ropes: Soft, Flexible, and Widely Used

Cotton ropes originate from the cotton plant (Gossypium spp.), specifically the fluffy fibers surrounding the seeds called bolls. Unlike hemp, cotton has a softer and more pliable structure, lending to its widespread use in clothing and other textiles.

A 2017 study published in “Industrial Crops and Products” highlighted the differences in tensile strength between cotton and other natural fibers, including hemp. Cotton fibers, although less strong than hemp, are more flexible and stretchable.

The manufacturing process of cotton ropes is similar to that of hemp but differs mainly in the carding stage, where the fibers are aligned more closely, resulting in a smoother finish.

- Ginning: Separation of fibers from seeds.

- Carding: Aligning the fibers.

- Spinning: Turning fibers into yarn.

- Twisting: Combining yarns to create the rope.

Both hemp and cotton have unique properties derived from their respective plant origins. Hemp, with its long history and robust fibers, offers strength and durability. Cotton, on the other hand, provides a softer and more flexible alternative.

These differences in composition and characteristics lead to varying applications in industries ranging from shipping to fashion, reflecting the versatility of natural fibers in the modern world.

Comparative Strength: Is Hemp Rope Really Stronger than Cotton?

The comparison between hemp and cotton ropes in terms of tensile strength is a topic of significant interest, especially in industries such as shipping, construction, and outdoor adventure. Let’s dive deeper into the details, backed by scientific studies and reliable sources, to provide a comprehensive understanding of their comparative strengths.

- Hemp’s Superior Tensile Strength: According to a 2016 study published in the “Journal of Textile Engineering & Fashion Technology,” hemp fibers were found to possess a tensile strength of approximately 550-900 MPa (megapascals), a measurement that quantifies the ability to withstand pulling forces. This strength is attributed to the long, robust fibers and the specific way they are spun.

- Cotton’s Relative Weakness: In contrast, cotton’s tensile strength ranges from 400-500 MPa, as noted in a comparative analysis in the “Journal of Applied Polymer Science.” This relative weakness is due to the shorter, more elastic fibers of cotton, which provide softness but less rigidity and resistance to pulling forces.

- Factors Influencing Strength: The differences in tensile strength between hemp and cotton ropes are also influenced by other factors such as the spinning technique, fiber treatment, and environmental conditions. A detailed study in “Fibers and Polymers” showed that the way fibers are processed and aligned can greatly impact the final strength of the rope.

- Practical Applications and Choices: Depending on the application, the choice between hemp and cotton rope may hinge on these strength characteristics. For instance, industries requiring robust and resilient ropes may opt for hemp, whereas applications prioritizing flexibility and comfort may choose cotton.

- Environmental Considerations: A 2015 study published in “Sustainability” highlighted hemp’s additional advantage in terms of environmental impact, with less water consumption and pesticide use compared to cotton. This not only positions hemp as stronger but also as a more sustainable option.

The higher tensile strength of hemp ropes, supported by various scientific studies and research, clearly establishes them as a stronger option compared to cotton ropes.

Economic Considerations: What Are the Costs Involved?

Economic aspects indeed play a vital role in deciding between hemp and cotton ropes. While the choice might seem simple, several underlying factors must be considered.

- Production Costs: Growing hemp is generally more cost-effective than growing cotton. According to a report by the Congressional Research Service, the input costs, including water, fertilizers, and pesticides, are typically lower for hemp. This, in turn, makes the overall cost of hemp production more favorable.

- Processing and Manufacturing: The processing of hemp can be more labor-intensive compared to cotton, as it requires specialized machinery. The “Journal of Agricultural and Applied Economics” notes that these additional processing requirements might increase the final cost of hemp products.

- Retail Pricing: Despite the lower cultivation costs, hemp ropes are often more expensive than cotton ropes in retail. This is partly due to the limited availability of specialized hemp processing facilities and a smaller market share, as highlighted by a study in the “International Journal of Business and Economics.”

- Market Trends and Regulations: Legislation and market trends can also influence the costs. In countries where hemp cultivation is strictly regulated, the prices might be higher. An overview by the “Journal of Industrial Hemp” suggests that governmental policies can significantly impact the economic feasibility of hemp production.

- Consumer Demand and Perception: Lastly, the perception and demand for environmentally friendly products can alter pricing strategies. A study from the “Journal of Consumer Behaviour” indicates that consumers’ willingness to pay more for sustainable products like hemp could influence its market pricing.

Health and Safety: Are There Any Health Risks or Benefits?

When evaluating hemp and cotton ropes, one must not overlook health and safety considerations.

- Allergic Reactions and Sensitivity: Some individuals might be allergic or sensitive to hemp fibers. However, these cases are rare and often milder compared to allergic reactions to other natural fibers, as described in the “Journal of Dermatological Science.”

- Chemical Exposure: Since cotton farming often requires more pesticides, residual chemicals may remain in the final product. A report from the Pesticide Action Network UK has detailed that exposure to these residues might pose health risks, particularly for those handling cotton regularly.

- Biocompatibility: Hemp fibers are often considered more biocompatible with human skin. A study in “Textile Research Journal” suggests that hemp’s anti-microbial properties make it a preferred choice for medical applications, including bandages and medical ropes.

- Eco-Health Considerations: The environmental benefits of hemp, such as reduced water and chemical usage, indirectly contribute to broader public health by reducing pollution and promoting cleaner air and water, according to the “Journal of Environmental Health.”

Conclusion

In the comprehensive examination of hemp and cotton ropes, the scientific evidence strongly underscores the superior tensile strength of hemp. Studies published in reputable journals have quantified hemp’s strength at approximately 550-900 MPa, contrasting with cotton’s 400-500 MPa. The innate characteristics of hemp fibers, including their robustness and elasticity, contribute to this strength, making hemp ropes a stronger option than cotton ropes.

This strength, coupled with other considerations like environmental impact and economic factors, makes the choice between hemp and cotton ropes a nuanced decision, dependent on specific needs and preferences. The definitive conclusion, supported by empirical research, is that hemp rope is indeed stronger than cotton rope.

FAQs

What are the disadvantages of hemp fabric?

Hemp fabric, although appreciated for its strength and environmental friendliness, does come with some disadvantages. It can be less soft and more coarse compared to other natural fibers like cotton. Additionally, the processing of hemp fabric can be more labor-intensive, requiring specialized machinery and techniques. This can lead to higher retail costs. Furthermore, the limited availability of hemp products in certain regions may reduce accessibility for consumers.

Is Manila rope the same as hemp?

Manila rope and hemp rope are not the same, though they are often confused due to their similar appearance. Manila rope is made from the fibers of the abacá plant (Musa textilis), whereas hemp rope is made from the fibers of the Cannabis sativa plant. Manila rope is known for its flexibility and resistance to saltwater, making it popular for marine applications. Hemp rope, on the other hand, is recognized for its overall strength and durability.

Is hemp more durable than cotton?

Yes, hemp is generally considered to be more durable than cotton. Studies in the “Journal of Textile Engineering & Fashion Technology” have highlighted the greater tensile strength of hemp fibers, attributed to their longer and more robust structure. This makes hemp fabrics and ropes more resistant to wear and tear, giving them a longer lifespan compared to their cotton counterparts.

Is hemp stronger than steel?

While the comparison between hemp and steel might seem unconventional, hemp fibers are often touted for their exceptional strength-to-weight ratio. However, steel, being a metal alloy, has a significantly higher tensile strength than hemp. The comparison usually arises in the context of specific applications where the flexibility and resilience of hemp fibers may offer advantages over steel, such as in automotive composites. In a direct comparison of tensile strength, steel is stronger, but hemp may offer other functional benefits depending on the context.

Is hemp stronger when wet?

Hemp fibers do exhibit a tendency to increase in strength when wet. The water acts as a binding agent between the fibers, increasing the friction and thereby enhancing the tensile strength. However, continuous exposure to moisture might lead to deterioration over time. It’s essential to consider the specific application and environment to determine if the wetting of hemp will be beneficial or detrimental.